Reverse osmosis is a process which uses a membrane under pressure to separate relatively pure water (or other solvent) from a less pure solution. It is a process being adopted for wastewater treatment in the cooling tower.

Hydro fan has been installed in order to reduce energy consumption and CO2 emissions at the cooling tower. It features high efficiency cooling blades. Opting for these blades, we can reduce power consumption.

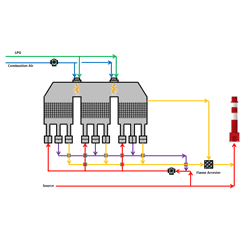

RTO or regenerative thermal oxidizer is a type of air pollution control equipment designed to decompose volatile organic compounds (VOCs) used in our industrial process.

An installation of noise monitor equipments helps collect real-time data resulted from measurements of noise in the community. This provides information for continued improvement of wellbeing of a workforce and surrounding community as preventing potential impact from our industrial activity.

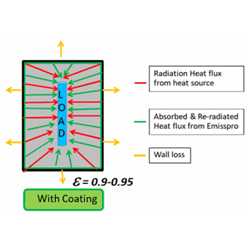

The application of high emissivity coatings in reheating furnaces, in this case up to around 190 m2 in thickness, can improve the heat transfer from furnace to steel billets to effectively increase radiant heat transfer and save energy without compromising process reliability and safe operation. Higher emissivity also corresponds to an increase in thermal efficiency. More importantly, with coatings, we effectively reduce greenhouse gas or GHG: LPG consumption drops 10 kilogram per hour and CO2 260 tonnes per year.

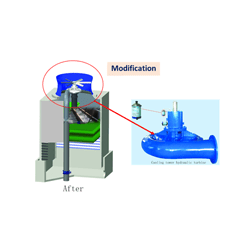

The hydro-fan technology has replaced the conventional electric fan turbines that are necessary in cooling down the temperature and improving air circulating in the industrial premises. Owing to this modification, we save the cost of electricity and promotes the use of greener energy in the operation. Since 2010, UCHA plant has installed 2030 hydro-fan units. This equates to 310 kWh saved in total electricity savings; an estimate of 1189 tonnes per year of CO2 emission obviated.

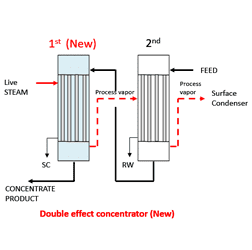

Waste liquor is the by-product of the industrial process. After the evaporation process solid in black liquor is produced and it is combustible before being fed into a large unit of recovery boiler, for the energy production and chemical recovery purposes. At our plants, double-effect technology which enables much lower steam consumption replaced the single-effect which consumes a staggering amount of steam at 4.6 tonnes per hour. The improved version reduces steam consumption by half when compared with its predecessor, at 2.5 tonnes per hour, equivalent to CO2 emission of 3,100 ton/year saved.

To propel the absorption chiller at the industrial plant, only low grade waste heat and hot water alone is used. Rather than electricity used in a large amount, the chiller can rely on recycled energy, resulting in approximately 230 kWh being saved, which is equivalent to an CO2 emission of 882 tonnes per hour.